The Secret to Solving UPS Design Challenges

In the modern industrial landscape, the demand for reliable, efficient and high-power Uninterruptible Power Supply (UPS) has never been greater. Silicon Carbide (SiC) has emerged as a solution which offers superior efficiency, thermal management and power density compared to traditional silicon-based power electronics, making it ideal for high-power UPS systems.

In the modern industrial landscape, the demand for reliable, efficient and high-power Uninterruptible Power Supply (UPS) has never been greater. The UPS plays a critical role in ensuring continuous power delivery, especially in high-power applications where even a brief interruption can adversely impact personal safety, operational readiness and financial stability. As industries rely more on continuous power for critical operations, the demand for advanced materials and technologies to enhance UPS performance is growing.

Traditional silicon-based power electronics have served the industry well, but as the demand for higher efficiency, greater power density and improved thermal management grows, Silicon Carbide (SiC) has emerged as a transformative material in the design and implementation of high-power UPS systems.

What is an Uninterruptible Power Supply?

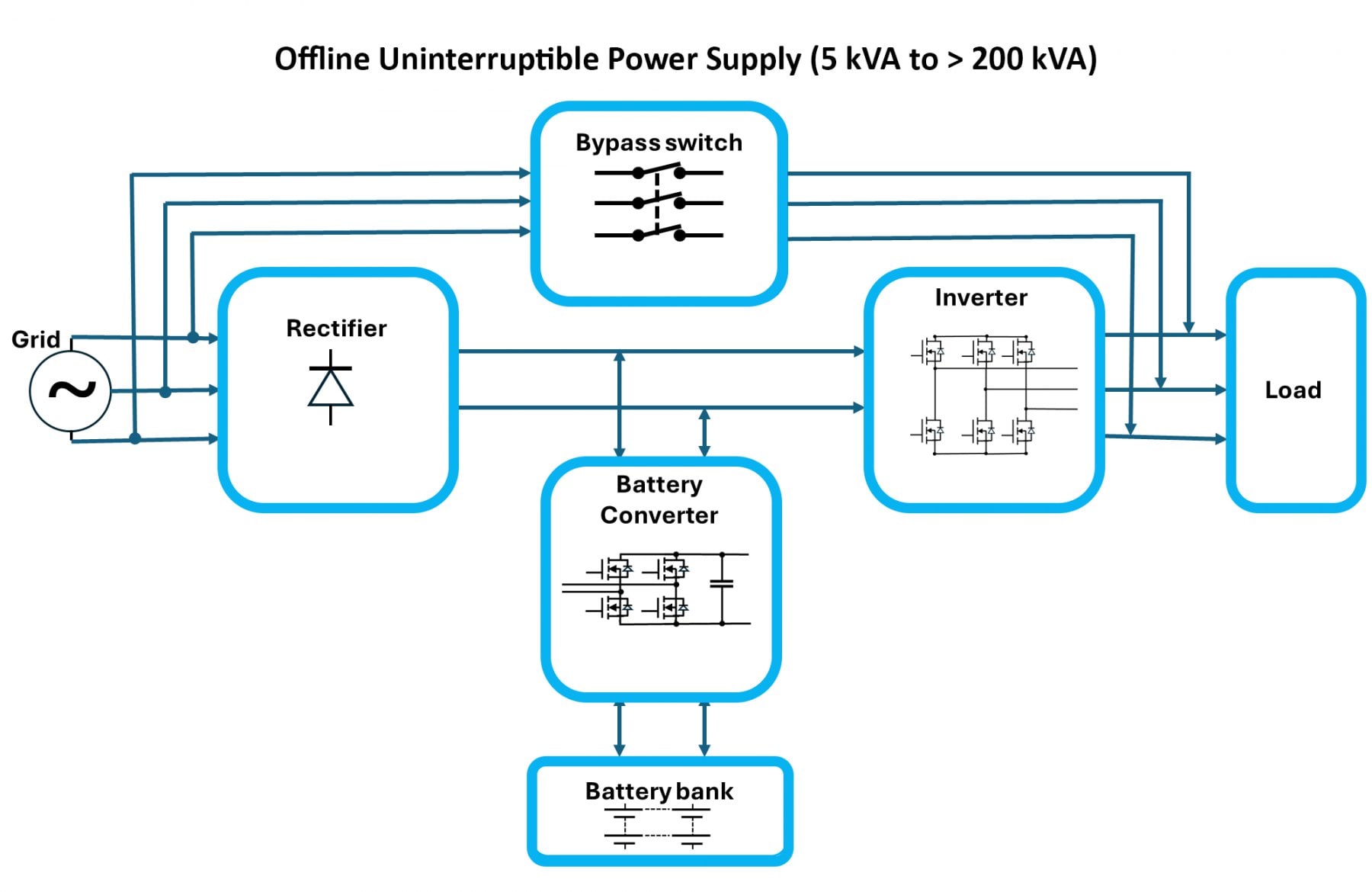

A high-power UPS is a system designed to provide continuous power to critical equipment during power outages, voltage sags or other electrical disturbances. These UPS systems are essential in environments where power reliability is paramount, such as manufacturing plants, data centers, hospitals and critical infrastructure facilities.

As the name implies, the primary function of a high-power industrial UPS is to ensure uninterrupted power delivery. It achieves this by incorporating a battery or other energy storage system that kicks in immediately when the primary power source fails. The UPS system typically includes an inverter that converts the stored DC power from the batteries into AC power, which is then supplied to the connected equipment.

|

Key components of a high-power industrial UPS include rectifiers, inverters, batteries and control systems. The rectifier converts incoming AC power to DC to charge the batteries and power the inverter. The inverter then converts this DC back to AC to supply the load. Advanced UPS systems also feature power conditioning capabilities, which filter and regulate the power to protect sensitive equipment from voltage spikes, surges and noise.

|

The Need for Advancement

High-power UPS systems are essential in various industrial sectors. These systems are designed to provide a seamless transition to backup power during outages, ensuring that sensitive equipment remains operational. However, the increasing complexity and power demands of modern industrial applications have exposed the limitations of conventional silicon-based power electronics.

SiC is a wide-bandgap (WBG) semiconductor material that offers superior electrical properties compared to traditional silicon. SiC devices, such as MOSFETs and diodes, can operate at higher voltages, temperatures and switching frequencies, making them ideal for high-power applications. The adoption of SiC technology in UPS systems promises to enhance efficiency, reduce system size and improve overall reliability.

Design Challenges

Designing high-power UPS systems presents several significant challenges. One of the primary issues is efficiency. Traditional silicon-based power devices, such as Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), exhibit higher conduction and switching losses, which can lead to substantial energy waste and increased operational costs. This inefficiency is particularly problematic in high-power applications where even small losses can translate into significant energy dissipation.

Thermal management is another critical challenge. High-power UPS systems generate substantial heat, which must be effectively dissipated to prevent overheating and ensure reliable operation. Silicon-based devices often require extensive cooling solutions, such as large heatsinks or active cooling systems, which add to the overall size, weight, complexity and cost of the UPS.

Size and weight constraints are also a concern. Industrial environments and data centers often have limited space for power equipment and the trend towards miniaturization demands more compact and lightweight solutions. Traditional silicon-based UPS systems, with their bulky cooling requirements and lower power density, struggle to meet these demands.

High power UPS design challenges include:

- Efficiency and Power Loss

- Thermal Management

- Power Density

- Switching Speed

- Reliability and Longevity

Overcoming Design Challenges

SiC technology addresses these challenges through its advanced WBG material properties. SiC devices, such as MOSFETs and Schottky diodes, offer significantly lower conduction and switching losses compared to their silicon counterparts. This results in higher efficiency, reducing energy waste and operational costs, leading to a longer backup run time. For high-power UPS systems, efficiency gain in roundtrip efficiency is crucial. There are losses in the rectifier (or PFC) when storing the energy and losses when discharging through the inverter. Using SiC in both power stages improves the overall roundtrip efficiency compared to Si.

The thermal conductivity of SiC is another key advantage. SiC has a thermal conductivity approximately three times higher than silicon, which enables more effective heat dissipation. This property allows SiC devices to operate at higher temperatures without the need for extensive cooling solutions. As a result, UPS systems can be designed with smaller heatsinks or even passive cooling, reducing the overall size and weight of the system.

SiC's high breakdown electric field strength also contributes to its superior performance in high-power applications. This property allows SiC devices to handle higher voltages and currents without breaking down, making them ideal for use in high-power UPS systems. The ability to operate at higher voltages and currents enables the design of more compact and efficient power stages, further reducing the size and weight of the UPS.

In addition to these material advantages, SiC devices enable faster switching speeds compared to silicon devices. This characteristic is particularly beneficial for power conversion applications, such as inverters and rectifiers used in UPS systems. Faster switching speeds result in lower switching losses and improved overall efficiency. Moreover, the reduced switching losses allow for higher switching frequencies, which can lead to smaller passive components, such as inductors and capacitors, further reducing size and cost of the UPS.

Benefits of SiC in high power UPS applications:

- Enhanced efficiency

- Superior thermal management

- Increased power density

- Faster switching speeds

- Improved reliability and longevity

|

System Integration Benefits

We understand the complexities of designing high-power UPS systems and recognize that integrating advanced technologies like SiC requires thoughtful system-level design considerations. Our comprehensive mSiC™ product portfolio provides a wide range of SiC components that seamlessly integrate into every critical part of your system, enhancing performance, efficiency and reliability.

By leveraging SiC technology at different levels of your UPS system—from rectifiers and inverters to battery interfaces and power conditioning—you gain a cohesive, high-performance system that addresses key operational challenges.

The integration of mSiC products into your system enables:

- Higher System Efficiency: Reduced energy losses mean lower operational costs and more sustainable energy consumption.

- Improved Thermal Management: Effective heat dissipation allows components to operate at higher temperatures without bulky or complex cooling solutions.

- Compact Design Flexibility: Our modules and discrete devices facilitate smaller form factors, meeting stringent space constraints.

- Enhanced Reliability and Longevity: SiC’s robustness against breakdowns and higher temperature capability contribute to longer system lifetimes with reduced downtime.

Our commitment to performance and reliability is reflected in our rigorous testing protocols, ensuring that every product meets industrial-grade standards. Every component in our mSiC product portfolio is designed to deliver consistent, reliable performance even in the harshest environments and critical industrial applications.

By integrating our advanced mSiC technology into your high-power UPS systems, you are not only leveraging cutting-edge materials but also adopting a solution that enhances operational efficiency, reduces costs and guarantees system longevity—providing your industrial operations with the reliability and continuity that modern infrastructure demands.

|

Design Tools and Support

To further support designers, we offer a suite of SiC design resources, simulation tools and comprehensive technical and customer support. Our design resources include detailed application notes, reference designs and evaluation boards which help engineers accelerate the development process and optimize their designs.

Our advanced simulation tools allow for precise modeling and analysis of SiC devices within specific applications, enabling designers to predict performance and identify potential issues early in the design phase.

Additionally, our support team offers expert guidance and troubleshooting assistance, ensuring that customers can effectively integrate SiC technology into their UPS systems. This holistic approach to support underscores our dedication to empowering engineers with the tools and knowledge needed to leverage the full potential of SiC in high-power applications.

Summary

The adoption of silicon carbide in high-power uninterruptible power supplies (UPS) represents a significant advancement in power management. The adoption of SiC in UPS systems enhances efficiency, reduces size and improves thermal management, addressing key design challenges in high-power industrial environments.

Our comprehensive SiC portfolio, including MOSFETs, Schottky diodes, power modules and gate drivers provides the necessary building blocks for designing highly efficient, compact and reliable UPS systems.

As industries continue to demand more reliable and efficient power solutions, the role of SiC in high-power UPS systems will continue to grow. It’s clear that SiC technology holds the key to meeting the evolving needs of industrial power management. With continued innovation and development, SiC will undoubtedly play a pivotal role in shaping the future of uninterrupted power for critical operations.