Enhance Efficiency in Battery Energy Storage Systems with Silicon Carbide

In the rapidly evolving landscape of modern power systems, energy storage systems (ESS) play a crucial role in ensuring reliability, efficiency and sustainability. Silicon Carbide (SiC) is a revolutionary technology in the realm of power electronics that can help solve many challenges when designing an ESS.

Enhance Efficiency in Battery Energy Storage Systems with SiC

In the rapidly evolving landscape of modern power systems, energy storage systems (ESS) play a crucial role in ensuring reliability, efficiency and sustainability. However, designing an effective ESS comes with its own set of challenges, including managing costs, optimizing technical performance and navigating regulatory and environmental considerations.

Silicon Carbide (SiC) is a revolutionary technology in the realm of power electronics that can help solve many challenges when designing an ESS. With its superior properties, SiC offers significant advantages over traditional silicon (Si), promising enhanced safety, efficiency and overall performance for ESS. We will explore how SiC can address the key challenges in ESS design and how our innovative solutions can help power system designers seamlessly integrate SiC into their next project.

|

What is an Energy Storage System?

Energy storage involves capturing energy produced at one time for use later to balance energy demand and production. The process of energy storage converts energy from forms that are challenging to store into forms that are more convenient or economical to store.

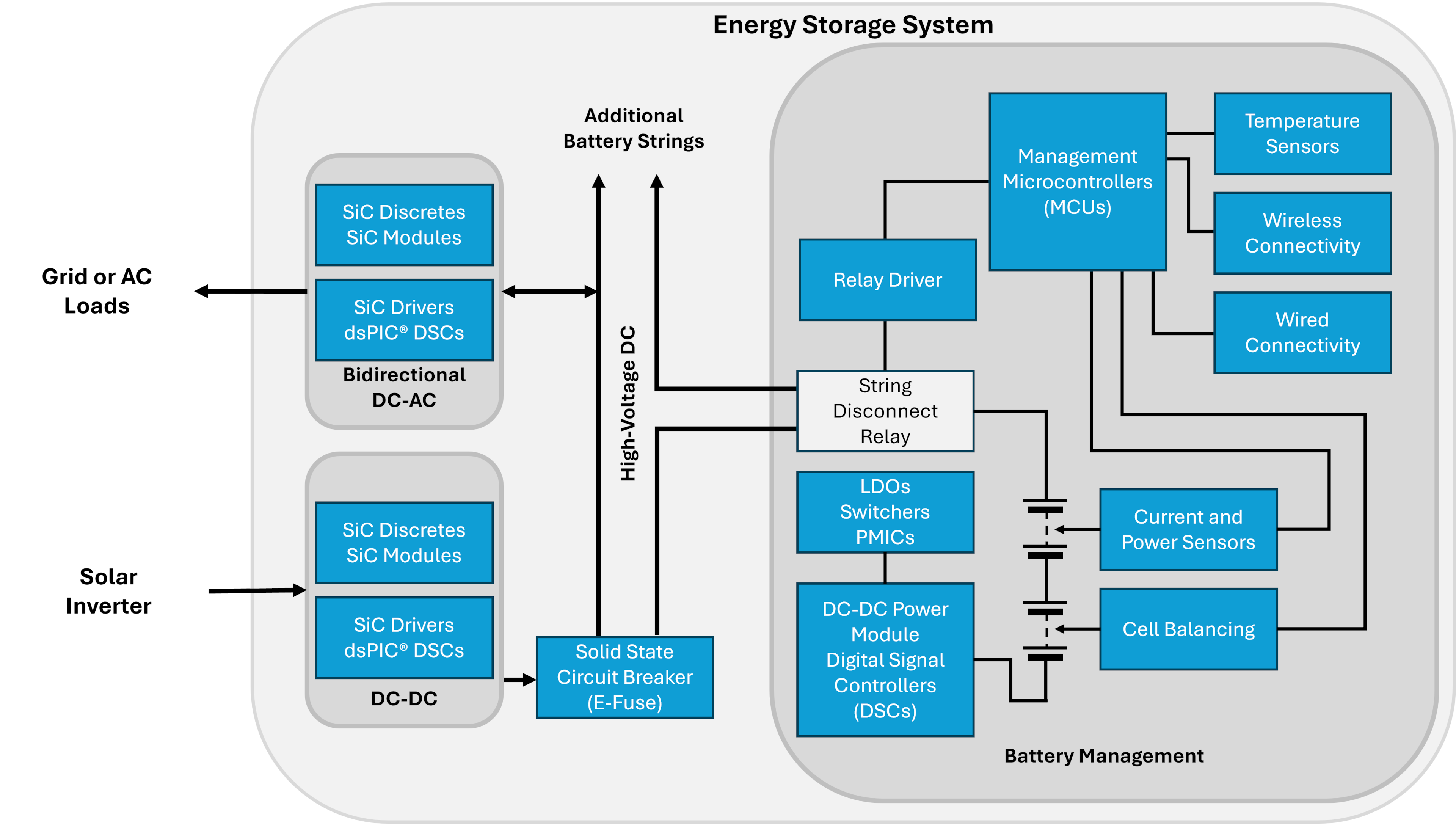

A Battery Energy Storage System (BESS) is an ESS that uses an array of batteries to store electrical energy for later use, enhancing reliability, efficiency and sustainability in modern power systems. Key components include batteries, a Power Conversion System (PCS), an Energy Management System (EMS) and auxiliary systems. Batteries, such as lithium-ion (Li) or lead-acid (PbA), store energy, while the PCS converts energy between direct current (DC) and alternating current (AC) as needed.

Core components include:

- Batteries

- Power Conversion System (PCS)

- Energy Management System (EMS)

- Various other auxiliary systems

The BESS captures excess energy during low demand or high production periods, converting AC to DC for storage. The EMS monitors battery health and optimizes storage. When demand exceeds supply, the BESS discharges energy, converting DC back to AC to balance supply and demand.

A BESS provides grid services like peak shaving, load leveling and backup power during outages. The EMS ensures efficient operation, prolongs battery life and maximizes economic benefits through real-time data and control. BESS is crucial for integrating renewable energy, smoothing out production variability and enabling energy time-shifting, thus supporting a stable and sustainable power grid. In summary, BESS is vital for energy management, grid stability and renewable energy integration.

|

Challenges of BESS Power Systems

Economic Viability

The economic aspects of BESS are a major hurdle. The initial capital costs are substantial, encompassing the price of the batteries, power conversion systems and installation. High-quality batteries are particularly expensive due to the cost of raw materials and manufacturing processes. Additionally, operational costs, including ongoing maintenance, management and potential battery replacements, can be significant over the system's lifespan.

Ensuring economic viability requires a thorough analysis to demonstrate a return on investment. Mechanisms like peak shaving, load leveling and participation in energy markets must be carefully planned to justify the high initial and operational expenditures.

Technical Performance and Reliability

Selecting a technology with high energy density and efficiency is essential. However, batteries degrade over time due to chemical reactions during charge and discharge cycles. Ensuring long-term reliability involves managing this degradation and implementing strategies to extend battery life. Seamless integration with the existing power grid requires robust engineering solutions to manage power quality and ensure compatibility with grid standards.

Regulatory and Environmental Considerations

Compliance with safety standards, grid interconnection requirements and environmental regulations is essential. The production, operation and disposal of batteries can have significant environmental impacts. Safety concerns, particularly regarding thermal management and chemical stability, require advanced monitoring systems and emergency protocols to mitigate risks.

Advantages of SiC in ESS Design

Bidirectional Power Flow and Efficiency

One of the key advantages of SiC MOSFETs over traditional Si or IGBT technologies is their ability to conduct current in both the first and third quadrants, enabling true bidirectional power flow. This is essential for modern ESS applications, particularly in advanced topologies like the totem-pole or half-bridge converters, which rely on low-loss bidirectional operation.

SiC devices feature a body diode with low reverse recovery charge, a critical property for reducing losses during high-frequency switching. This makes SiC superior to Si-based MOSFETs and IGBTs, where reverse recovery losses are higher, leading to reduced efficiency in such topologies. For instance, Si superjunction (SJ) devices are less suitable for totem-pole topologies due to their higher reverse recovery losses, which compromise efficiency.

IGBTs with antiparallel diodes can achieve bidirectional power flow; however, the reverse direction operates in uncontrolled rectification mode, resulting in poorer power factor and higher harmonics. By contrast, SiC MOSFETs provide controlled and efficient bidirectional operation, enhancing overall system performance.

Ohmic Conduction Loss Characteristics

In partial-load conditions, which are common in ESS operations, SiC MOSFETs exhibit significantly lower ohmic conduction losses compared to IGBTs. This characteristic is particularly important because energy storage systems often operate at partial loads, where IGBTs, due to their bipolar conduction nature, suffer from higher conduction losses. Over the lifespan of the ESS, these efficiency gains translate into substantial energy savings, effectively offsetting the higher initial cost of SiC devices. For electric vehicle (EV) applications, this efficiency gain extends battery runtime, making SiC a popular choice for traction inverters.

Compact and Cost-Effective Designs

SiC devices’ ability to operate at higher switching frequencies allows for smaller passive components, such as inductors and capacitors. Combined with reduced cooling requirements due to lower thermal losses, this enables more compact and cost-effective designs. The initial premium of SiC components is often outweighed by savings in auxiliary component costs and the improved energy efficiency over the system’s lifetime.

|

Tools and Solutions for Integrating SiC

Starting a design project with SiC without prior familiarity may leave you with a mix of curiosity, excitement and/or apprehension. We offer a comprehensive suite of tools and solutions which help to integrate silicon carbide into your energy storage system design.

To facilitate the integration of SiC into ESS designs, we provide an array of design and development tools. These include advanced design software and simulation tools with our MPLAB® SiC Power Simulator, which allows engineers to model and optimize their systems before implementation. Additionally, our evaluation boards and reference designs serve as practical starting points for developing SiC-based solutions, streamlining the design process and reducing time to market.

We also offer support through a wealth of technical resources and support services. This includes SPICE and PLECS models for FETs and SBDs, detailed application notes, informative webinars and dedicated customer support to assist with any challenges that may arise during the design and implementation phases. These comprehensive tools and resources help to add value as a partner in the development of your next cutting-edge SiC-based energy storage system.

Summary

Designing with SiC devices offers a multitude of benefits for energy storage system design, including significant cost savings, enhanced technical performance and robust regulatory compliance. SiC devices reduce overall system costs through lower cooling requirements and smaller passive components, while their superior efficiency leads to reduced operational expenses and extended lifespan. The improved energy density, durability and reliability of SiC components further contribute to their appeal. SiC's high switching frequency and power handling capabilities ensure seamless grid integration, meeting stringent safety and performance standards.

We encourage power system designers to consider SiC for your next ESS project to leverage these advantages. By integrating SiC, you can achieve a much more efficient, reliable and cost-effective energy storage solution that meets the demands of modern power grids.

To get started, explore our extensive range of mSiC™ products and solutions. With our comprehensive portfolio of MOSFETs, diodes and modules, along with advanced design software, evaluation boards and technical support, we help you adopt SiC with ease, speed and confidence.