Why FPGAs Excel at OPC UA Applications

This post gives an overview of OPC UA integration and why FPGAs are an optimal way to deploy the architecture.

Transforming Industrial Connectivity with OPC UA and FPGAs

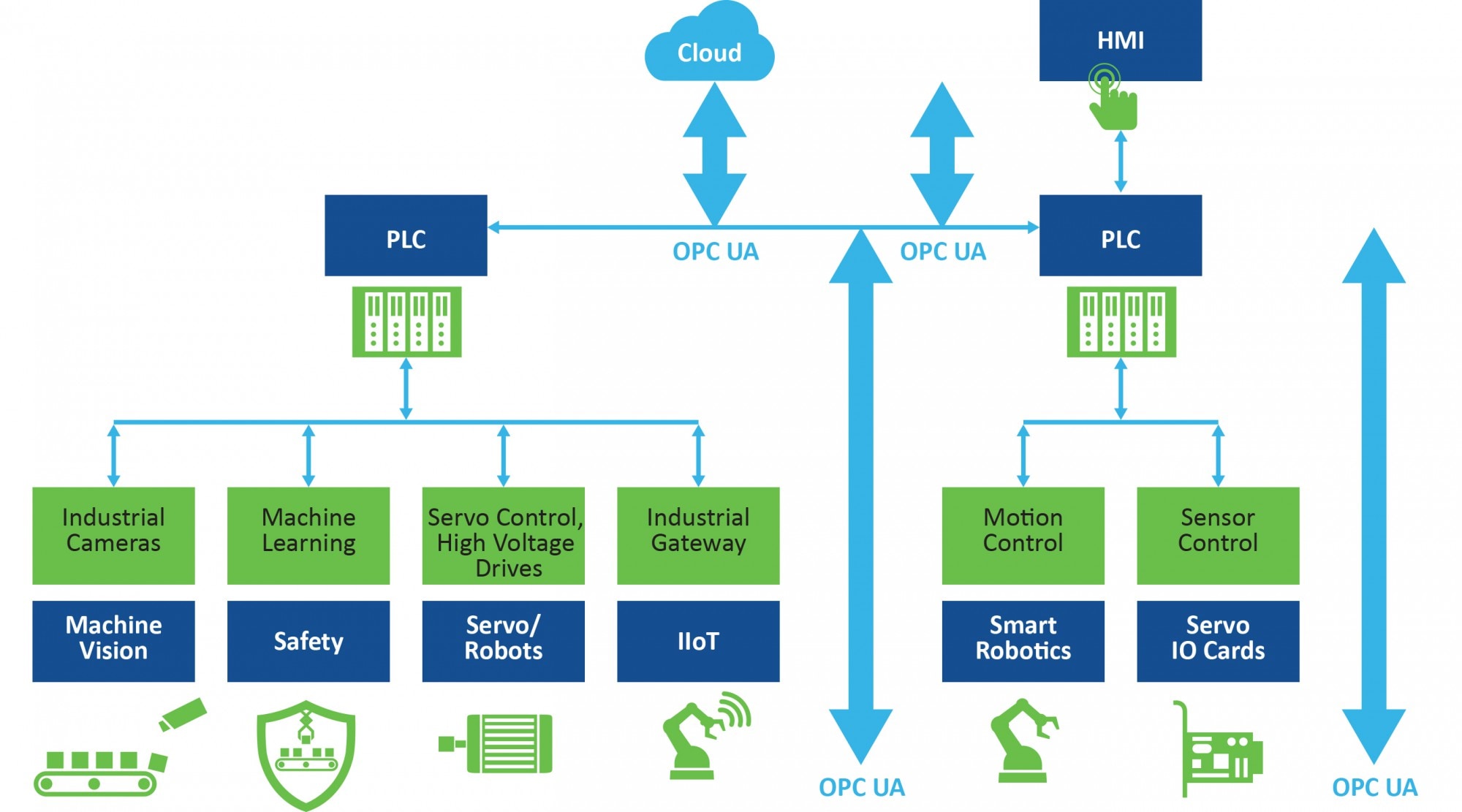

In the realm of industrial connectivity, OPC Unified Architecture (UA) stands tall as a transformative force, reshaping the landscape of data exchange and interoperability. Originating from the Open Platform Communications (OPC) Foundation, OPC UA has emerged as a robust, vendor-neutral standard, fostering seamless communication across diverse industrial systems. While there are a variety of ways to deploy OPC-UA, Field Programmable Gate Arrays (FPGAs) excel at this industrial data exchange standard. Among the characteristics of FPGAs are flexibility, scalability and implementation speed while providing the robustness, security and power efficiency demands of industrial manufacturing.

Understanding OPC-UA

At its core, OPC UA serves as a protocol for secure and reliable data exchange between industrial automation devices and systems. Its versatility lies in its ability to transcend the limitations of disparate technologies and protocols, facilitating interoperability between devices from various manufacturers, thus promoting a unified ecosystem. A standout feature of OPC UA is its platform independence. By transcending operating systems, it facilitates communication across different hardware and software platforms, fostering a truly interconnected environment. Its comprehensive security measures, including encryption and authentication mechanisms, ensure the integrity and confidentiality of data transmission. FPGAs can be programmed with specific security features suited for OPC-UA communication. This is particularly important in industrial applications where data integrity and secure communication are paramount.

Enhanced Functionality

OPC UA not only facilitates data exchange but also offers advanced functionalities. Its ability to provide context-rich information—including data models and metadata—empowers systems to comprehend and interpret data effectively. Furthermore, it supports complex data structures, enabling the transmission of diverse information types, from simple sensor readings to comprehensive machine diagnostic data. FPGAs are programmable and can be reconfigured to adapt to different OPC-UA requirements or updates in the protocol standards. This makes them a versatile choice for evolving environments. FPGAs can also perform highly specific tasks in real time. Since OPC-UA often requires real-time communication and control in industrial applications, FPGAs can handle these tasks efficiently without the latency that might be associated with general-purpose processors. Unlike CPUs that might have varying processing times due to factors like caching and multitasking, FPGAs can offer deterministic processing times. This is crucial for industrial applications where timing and consistency are critical. Further, FPGAs have low-latency processing capabilities. In an OPC-UA communication stack, this means faster data processing and communication, which is vital for applications requiring quick response times, such as in process control or monitoring systems.

Industry Impact

The adoption of OPC UA has had a profound impact across industries. From manufacturing and energy to healthcare and beyond, its implementation has streamlined operations, enhanced productivity and paved the way for innovations such as the Industrial Internet of Things (IIoT) and Industry 4.0.

Industry Applications

The versatility of OPC UA finds resonance across an array of industries. In manufacturing, it facilitates real-time data exchange between machines, streamlining production and enabling predictive maintenance. Energy sectors leverage OPC UA for seamless integration of diverse systems, optimizing energy generation and distribution. Healthcare benefits from its ability to securely transmit medical device data, enhancing patient care and hospital efficiency. Transportation sectors utilize OPC UA for efficient logistics management and monitoring, ensuring smooth operations. Moreover, in smart cities, it acts as a backbone for interconnected systems, enabling efficient city management, from traffic control to waste management. Possibilities are endless with this innovative technology especially using FPGAs as development and delivery platforms.

Case in Point: Manufacturing application - with and without OPC UA

Imagine a traditional manufacturing setup lacking OPC UA integration, disparate machines and systems operating in isolation. Data generated by these machines often resides in silos, inaccessible or incompatible with other equipment. Maintenance relies on routine schedules rather than predictive analytics, leading to potential downtime and inefficiencies. Troubleshooting becomes a complex endeavor due to the lack of standardized communication protocols, hindering swift resolution of issues.

|

In contrast, in a manufacturing environment integrated with OPC UA, machines seamlessly communicate and share data in real-time. Production lines become interconnected, allowing for comprehensive monitoring and control. Predictive maintenance becomes feasible as data from various machines is aggregated, enabling the implementation of condition-based maintenance strategies. Operators have a holistic view of the entire manufacturing process, enabling swift identification and resolution of issues.

Standardized communication through OPC UA ensures interoperability, allowing for the integration of new machines or technologies without major disruptions.

In essence, OPC UA transforms manufacturing by creating an interconnected ecosystem where data flows seamlessly, enabling predictive maintenance, optimizing operations and facilitating efficient troubleshooting compared to traditional setups without this standardization.

Future Prospects

As industries evolve and technology advances, OPC UA continues to evolve as well. Its flexibility to adapt to new requirements and its strong foundation in interoperability positions it as a linchpin in the future of industrial connectivity.

In this context, our PolarFire® System-on-Chip (SoC) FPGA aligns with the evolving landscape of industrial connectivity and the advancing capabilities of OPC UA through the following points:

- The Lowest Power FPGA

- Adaptive Protocol Support

- Advanced Security Features

- Scalable Performance

- Edge Computing Capabilities

With the proliferation of edge computing in industrial settings, the PolarFire SoC FPGA's ability to support edge-based OPC-UA implementations positions it as a valuable enabler of distributed intelligence and real-time data processing at the network edge, aligning with future trends in industrial connectivity.

In summary, OPC UA represents the strength of standardized, secure and interoperable industrial communication, fostering efficiency, innovation and seamless system integration. Looking ahead, the PolarFire SoC FPGA complements the evolving industrial connectivity landscape and together, they pave the way for resilient and future-ready industrial connectivity solutions.