Rising Electric Vehicle Sales Impact Global Markets – and Automotive Design

By 2030, EVs are likely to account for 50% of new passenger vehicles sold. There are several reasons that help to explain this trend.

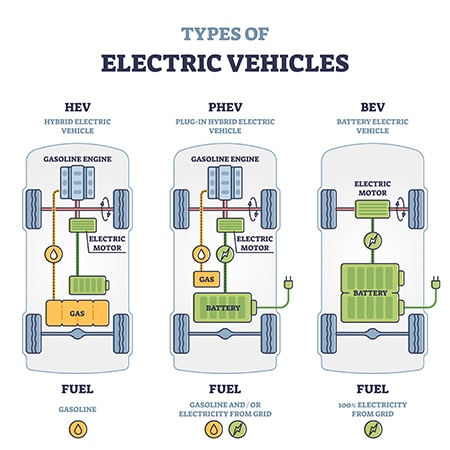

Sales of electric vehicles (EV) – both battery-electric vehicles (BEV) and hybrid/plug-in hybrid-electric vehicles (HEV/PHEV) – have been growing steadily in recent years, but the conditions now exist for that growth rate to accelerate dramatically. Globally, sales of EVs came to just over 3.1 million units in 2020 (representing a 4.7% market share), but an analyst firm Canalys predicts that by 2030, EVs will account for 50% of new passenger vehicles sold.

There are several reasons that help to explain this trend. The first of these is regulation – for example, at the recent COP26 climate change conference, governments, OEMs and other stakeholders signed an agreement to transition to 100% zero-emission sales of new cars and vans by 2040. The combination of incentives (lower taxes on EVs) combined with penalties (taxes on high emissions vehicles) needed to meet these targets will aggressively drive an increase in production and sales of EVs.

High prices are another reason consumers have been slow to switch to EVs. However, a projected 20x reduction in the cost of Lithium-Ion batteries by 2030 will help to make them more affordable. Similarly, the lack of EV charging infrastructure has been a barrier, but this problem will soon be overcome by the EU and US investing $60B by 2030 (rising to $192B by 2040) in the deployment of chargers. Likewise, the market for EV charging equipment in China is expected to reach an annual level of $43B USD by 2025[1]. Improved battery technology will also allow EVs to travel further, removing “range anxiety” as a concern for consumers.

In addition, societal perception of EVs is also changing. As consumers become more environmentally conscious and EVs become more commonplace, they are becoming more widely accepted. This is likely to become an even stronger trend that speeds up the move away from internal combustion engine (ICE) powered vehicles.

Figure 1: Types of Electric Vehicle

More Advanced Does Not Mean More Complicated

Ironically, while EVs represent a newer vehicle platform than ICE-powered vehicles, they are conceptually much simpler. Whereas an ICE vehicle has several hundred moving parts, EVs have fewer than two dozen. This makes them easier to manufacture, more reliable and therefore easier for consumers to maintain.

This simplification, combined with new remote design techniques using virtual reality and other advanced tools, is reducing the time it takes to complete automotive design. For example, an article on the design of the new Hummer EV concludes that “what historically took GM and other automakers five to seven years to develop and launch a new vehicle is expected to be cut to under three years.”

As automotive OEMs move to simpler EV production platforms, designers need to be ready for the shorter design cycles. This will in turn, provide for further cost reductions. According to a McKinsey Survey on BEV Production[2], the time taken to bring a BEV to market is 5% shorter than an ICE vehicle. Additional improvements could further reduce development times to between 23 and 28 months (a 20% improvement).

The move to EV production will also give OEMs the option to pursue different sourcing strategies, which also impact vehicle design processes. According to McKinsey, many suppliers are already offering more components outside of their original core areas. In one example, EV powertrain components are less complex than equivalent ICE engines, so OEMs may find it more efficient to outsource those systems instead of designing them in-house. This in effect makes the drivetrain more of a commodity over time, and doing so may pose a greater risk for OEM brands that emphasize driving performance.

Helping OEMs Streamline EV Design

Microchip has a broad portfolio of electronic components that have been designed into many EV applications. These can be used to streamline all aspects of EV design:

- Our AEC-Q100-qualified 8-bit, 16-bit, and 32-bit MCUs (single and dual core), Digital Signal Controllers (DSCs) and MPUs are suitable for digital power conversion and other embedded control systems throughout the entire EV.

- We have rugged and reliable Silicon Carbide (SiC) MOSFETs and Diodes which are ideal for on-board charging and power inverter applications. These devices are produced on our low-risk manufacturing process, and they can be conveniently evaluated using our real-world reference designs.

- Our TrustAnchor100 (TA100) CryptoAutomotive™ security IC provides a way to implement security into existing systems without requiring costly redesigns. It provides external Hardware Security Module (HSM) support for secure boot, CAN message authentication, authentication of EV battery management systems, Transport Layer Security (TLS), Wireless Power Consortium (WPC) 1.3 Qi® authentication, High-Bandwidth Digital Content Protection (HDCP) and many other features.

- We have a comprehensive portfolio of low-power analog solutions that includes a wide range of power management, linear, mixed signal, thermal management and interface products.

- Our inductive sensors are designed for the automotive environment to provide fast, precise position acquisition in rotary and linear position applications.

The Rivian R1T is an excellent example of how Microchip parts can be used in EV designs. It contains more than 50 of our ICs (including MCUs as well as analog, memory, RF, USB, Ethernet, timing and security devices), which are used in applications such as EV charging, telematics, central gateway module, Qi wireless charging and many more.

If you’re looking to accelerate your EV design, learn more about Microchip’s e-Mobility solutions here.

Get innovative automotive and transportation design solutions that will help get your products to market faster.

During Transportation Innovation Days 2022, which spans several online sessions, our experts and industry thought leaders will present live and on-demand content on topics including: e-Mobility, Advanced Driver-Assistance Systems (ADAS), capacitive touch, wired and wireless networking, cyber security, functional safety and automotive software.

Learn more about Transportation Innovation Days 2022 and register.

[1] https://wedc.org/export-from-wisconsin/market-intelligence/