Using the LX7720's Motor Drivers—Part 8: Connecting an LX7720 to Unipolar Stepper Motors

This blog is the 8th in a series that discusses the implementation aspects of the LX7720 spacecraft motor driver. It breaks down the LX7720's major functions into circuit blocks and sub-blocks and details how they work. This also explains the operation of sub-blocks and how they integrate into a motor drive system, helping designers to optimize their circuit designs.

As space system developers continually work to reduce the size, weight and power of key modules and elements, they also require higher-performance, radiation-hardened and radiation-tolerant components that enhance system designs. New technology–such as lighter, more highly integrated motor control circuits for satellites–can withstand extreme space environments and optimize spacecraft performance.

The LX7720 spacecraft motor driver is radiation hardened by design. It’s a companion integrated circuit (IC) to a space Field Programmable Gate Array (FPGA) such as Microchip’s RTG4 FPGA and RT PolarFire® FPGA, or a space microcontroller (MCU) such as Microchip’s SAMRH71F20 or SAMV71Q21RT. The integrated current sensing, resolver, encoder, and Hall Effect encoder interfaces in the LX7720 reduce board space and weight while increasing reliability for the closed-loop motor control using coil current feedback and rotor position sensing.

This is the final blog in an eight-part series that focuses on LX7720's motor driver and current sense circuits, starting with the theory of the blocks within the FET driver and current sensing stages, followed by selection of external components, and finally practical implementation of brushless DC, bipolar and unipolar stepper motors. The topics in this series are:

- Introduction to the half-bridge drivers and discussion of the charge pump approach used to generate independent gate supplies for each high-side N-channel Field-Effect Transistor (NFET)

- Practical half-bridge driver stages using both standard gate voltage and low gate voltage NFETs

- Introduction to the motor winding current sense amplifiers

- Topology choices applying current sense amplifiers within a half-bridge stage

- Separating a half-bridge into independent low-side and high-side drivers

- Connecting an LX7720 to a Brushless DC Motor (BLDC) or Permanent Magnet Synchronous Motor (PMSM), with optional electromagnetic brake

- Connecting an LX7720 to a bipolar stepper motor

- Connecting an LX7720 to one or two unipolar stepper motors

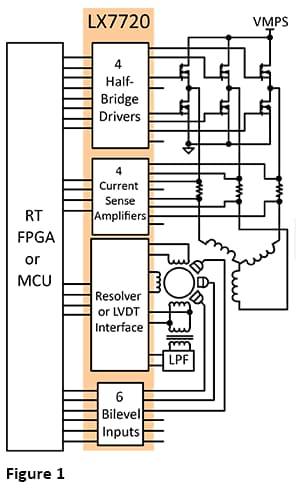

Typical Motor Drive System using LX7720

The LX7720 contains four half-bridge drivers with floating current sense for motor coil driving, six bi-level inputs (comparators) for sensing Hall Effect sensors and rotary encoders, and a complete resolver/LVDT interface with primary coil driver and secondary signal conditioning. Figure 1 shows a top-level block diagram for a typical motor drive system using the LX7720 and illustrates the benefit of integrating all the mixed-signal electronics for a closed loop motor driver within one IC.

Figure 1. Typical Motor Drive System using LX7720

The first few blog posts discussed the fundamentals of the LX7720’s half-bridge stages and integrated current sensing. The previous two blog posts discussed using the LX7720 with PMSM and BLDC synchronous motors and bipolar stepper motors. This blog post discusses using the LX7720 with unipolar stepper motors.

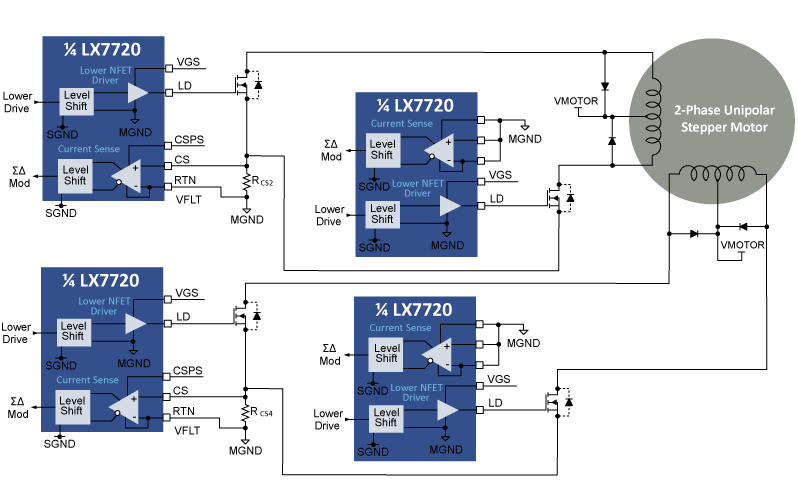

The LX7720 contains four half-bridge driver stages and four current sense amplifiers, which is enough to drive two 2-phase unipolar stepper motors with full current sensing. One motor uses the four high-side drivers and two current sense amplifiers. The other motor uses the four low-side drivers and the two remaining current sense amplifiers.

Two-Phase Unipolar Stepper Motor Driver with Ground Current Sensing

Figure 2 shows a generic 2-phase unipolar stepper motor being driven by four low-side drivers operating in pairs. The LX7720 circuitry is shown simplified, with supplies and decoupling to the current sense and gate drive sections omitted. The key components are the four half-bridges and the current sense.

Each low-side driver pair has current sensing in one of its half-bridge outputs. Since only one half of each unipolar winding is powered at a time, only two current senses are needed for full motor winding current measurement. In this application, the LX7720's two grounds SGND and MGND are joined together directly on the PCB.

The motor windings' center-taps are connected to the motor supply, VMOTOR. Since VMOTOR has no connection to the LX7720, this voltage can be different to the LX7720's normal VMPS motor supply, if desired. Motor winding currents flow in from VMOTOR through half a phase winding, and out to the motor ground MGND through a low-side FET and the current sense resistor shared by each phase winding. Diodes in parallel with each winding are necessary to recirculate winding current when a driver FET switches off.

Figure 2. Two-Phase Unipolar Stepper Motor Driver With Ground Current Sensing

Two-Phase Unipolar Stepper Motor Driver with Supply Current Sensing

Figure 3 shows the alternative configuration for a 2-phase unipolar stepper motor, now being driven by four high-side drivers instead of low-side drivers. Since the high-side drivers are used, the motor supply must be the LX7720's normal 20V to 60V VMPS motor supply.

The motor windings' center-taps are now connected to MGND, and ideally return to the driver board via a dedicated conductor to terminate at MGND there. In that case, the LX7720's two grounds SGND and MGND are joined together directly on the PCB. For situations where the motor ground will be terminated elsewhere, see the discussion about the LX7720's SGND and MGND ground domains in the 6th blog.

Motor winding currents flow in from the motor supply VMPS through half a phase winding, and out to the motor ground MGND through a low-side FET and a current sense resistor shared for each phase winding.

Figure 3. Two-Phase Unipolar Stepper Motor Driver with Supply Current Sensing

Synchronous motors are also available with more than 2-phase windings. Since the half-bridge and current sense stages are independent within an LX7720, multiple LX7720s can be used together to control a motor with more than two phases.

You should now understand the two alternative configurations to connect an LX7720 to a unipolar stepper motor. An advantage of the unipolar stepper motor type is that both configurations can be used at the same time, allowing a single LX7720 to drive two unipolar stepper motors. This results in further board space savings, weight reduction and increased reliability that is achieved with this highly integrated IC.

Learn more about the LX7720 and other radiation-hardened mixed signal ICs.

Read other parts of this series:

Part 2: Practical half-bridge driver stages using both standard gate voltage and low gate voltage NFETs

Part 3: Introduction to the motor winding current sense amplifiers

Part 4: Topology choices applying current sense amplifiers within a half-bridge stage

Part 5: Separating a half-bridge into independent low-side and high-side drivers