Semiconductor Packaging Miniaturization Services

World-Class Miniaturized Electronic Packaging Services

Advanced Packaging Capabilities

Secure the competitive advantage that we offer when you need high-precision and high-accuracy semiconductor solutions. Because we offer full microelectronic packaging services including design, substrate, assembly and test completely in house, there’s no need for you to invest in your own capital equipment. Here are some of our most popular services:

Substrate

- Rigid FR

- Flex-rigid

- Embedding

- LGA, BGA

- Ceramic

Assembly

- Wafer dicing

- Die attach

- Wire bond

- Encapsulation

- Flip chip

- SMT

- Serialization

Design

- Specification

- Schematic

- Layout

- Simulation—RF and power

- Mechanical—thermal and stress

Test

- Wafer probe

- PCBA functional test

- Socket design

- Software development

- Burn-in

Fully In-House Services

We specialize in designing, manufacturing, and testing complex semiconductors, which is done all in house.

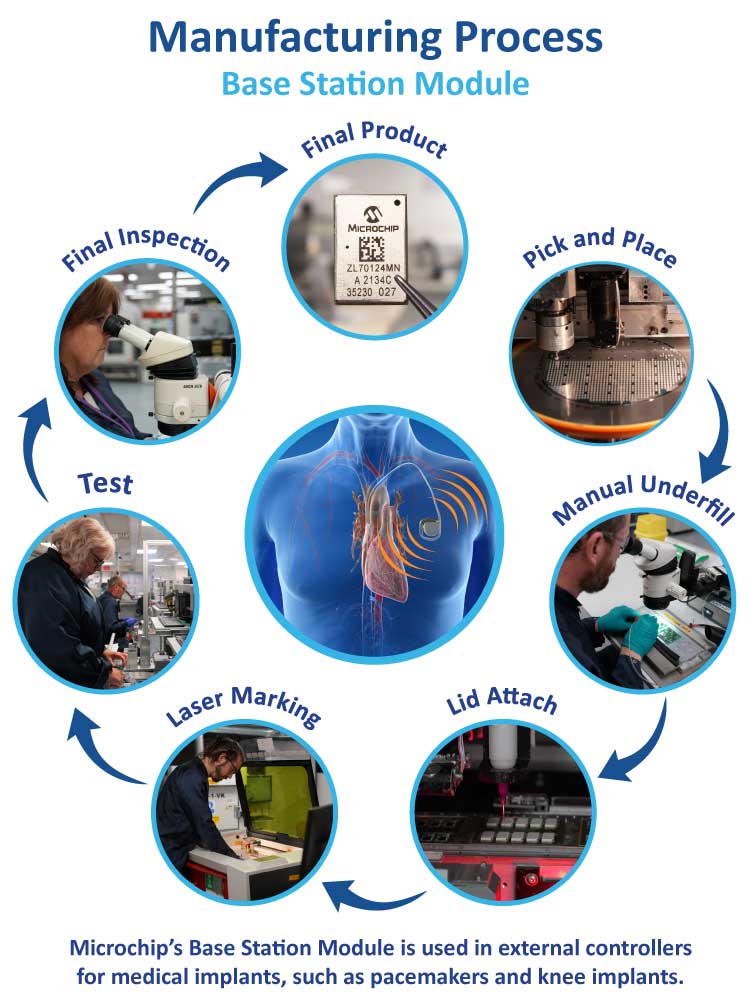

We currently manufacture two standard products to sell directly to customers. These are radio modules that are used in external controllers for implantable medical devices:

- MiniSIM (ZL70323)

- Base Station Module (ZL70123)

Markets Served

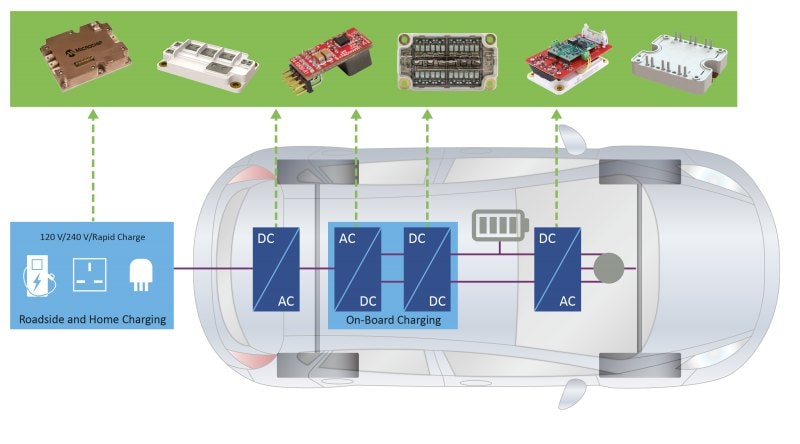

Automotive

Our automotive devices are supported by a variety of demonstration and evaluation kits, reference boards, software and detailed documentation to reduce your development time.

Medical

We manufacture modules for implantable devices. These leading-edge solutions are unrivaled in their small sizes and long product lifespans. We also manufacture base station modules that enable implants to communicate and transfer data effectively.

Space

With a decades-long track record for innovation, quality and reliability, we have played a pivotal role in a variety of space programs.

Aviation

The aviation sector continues to require higher levels of reliability and integration of electronics in modern aircraft systems. To meet these requirements, we offer leading-edge solutions that are based on decades of experience and provide established reliability.

Industrial

We are an established supplier of industrial-grade networking solutions, offering a broad portfolio of robust and highly integrated products. Our products significantly reduce the complexity and overhead of deploying Ethernet across a variety of industrial applications.

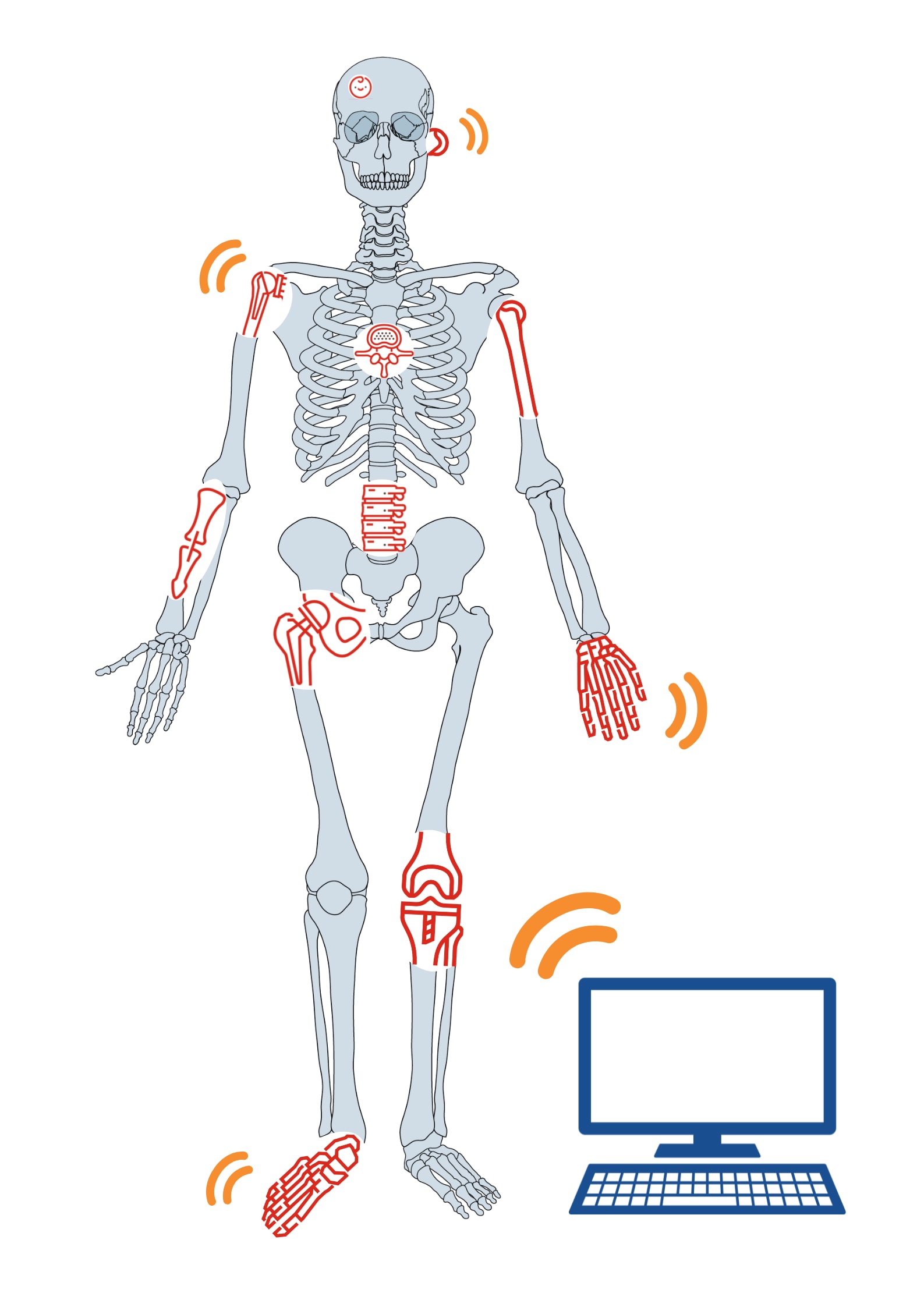

Miniaturized Electronics for Smart Implants

The first generations of implants were life-transforming inventions that saved and improved the lives of millions of people. Microelectronics are revolutionizing implant technology, replacing mechanical solutions with small and smart devices that meet Size, Weight and Power (SWaP) requirements. These new smart implants offer higher component density, more functionality and extended operational life.

We are partnering with medical companies to develop implants that can provide real-time data to doctors and patients. Devices that offer real-time communication can provide unprecedented benefits to the medical industry.

- Key Benefits

- Solving Customer Challenges

Key Benefits

- Smaller, lighter and more powerful products

- Consultant services

- Focus on quality

- Confidentiality

- Comprehensive system solutions

- Supply chain management

- Global support network

Solving Customer Challenges

One of our customers struggled to find a Printed Circuit Board (PCB) assembly supplier that was able to support the specific needs for developing an implantable device. Their key requirements for their supplier were:

- Full turnkey services

- Proven experience to improve their product’s SWaP

- Flexibility to manage their design iterations and take their project from low-volume prototypes to high-volume production

- Very high product reliability, minimal risk and a reliable source of resources and components

We were able to offer this customer:

- Highly flexible and agile processes

- Timely delivery

- Support for the highest quality standards, including ISO 9001 and IPC A 610

- High-yield assemblies

- A proven market leader

- A consistent supply of components

- One-on-one assistance

- Frequent contact via weekly calls and daily emails

- Consulting from our team

As a result of our collaboration, we were able to help this customer reduce size of their implantable product, which uses the ZL70103 RF transceiver, by 70%.

Contact Us

Microchip Advanced Packaging Services

Phase 2, Castlegate Business Park, Unit 4, Caldicot

Monmouthshire, South Wales, UK

NP26 5YW

Email Address: Info-Caldicot@microchip.com

Phone Number: (+44) 01291 435351