Solving Precision Timing Challenges in ADAS Systems

Modern vehicles use ADAS to avoid accidents daily and are loaded with other beneficial safety features. Here’s how timing solutions play a role in these systems.

Precision Timing

Precision timing provides a heartbeat to the computing and networking components that make up Advanced Driver-Assistance Systems (ADAS). The right timing solutions help drivers avoid collisions and enhance safety within modern vehicles.

In this blog post, we will discuss the critical role timing plays in ADAS.

ADAS and Timing Features in Modern Vehicles

The majority of modern vehicles have adopted standard ADAS features such as pedestrian detection and avoidance, lane departure warning and correction, traffic sign recognition, automatic emergency braking and blind spot detection. To support these advanced features, vehicles have progressed to become mobile data centers. They utilize high-speed Ethernet networks to interconnect multiple sensors, Electronic Control Units (ECUs) and communication gateways.

As modern vehicles become more complex, more precision timing components are required to support these features. More sensors need more oscillators. High-speed PCIe® and Ethernet networks demand more high-speed clocks. More computing can benefit from more multi-output clocks. Implementing these enhanced safety features pushes the need for increased timing content within vehicles.

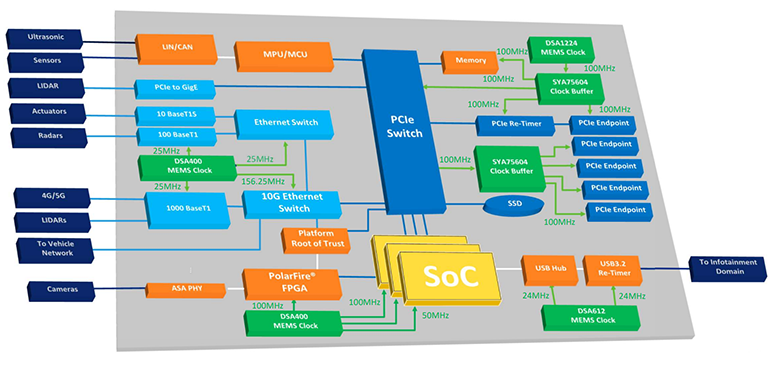

Highly Assisted/Autonomous Driving Vehicle Computer

Within modern vehicles, the ADAS ECU is at the core of these mobile data centers. This complex computer processes sensor and vehicle position inputs, computes driving instructions and sends control instructions to the engine, steering, braking and other functions. The central ECU is essentially the brain of the vehicle.

The components within the ECU are linked through high-speed PCIe switching, a desirable interface for tackling critical high-bandwidth and ultra-low latency computing requirements. To connect to peripherals and other ECUs, the ECU is connected through the vehicle Ethernet network. Ethernet delivers high-speed communication with less cabling, which reduces cost and weight. PCIe, Ethernet and other technologies all require high-frequency, low-jitter differential clock signals. In the representative ECU design above, there are fifteen different high-speed clocks.

Precision Clock Solutions

The precision clocks needed in these advanced designs have stringent requirements:

- High clock frequencies

- Low jitter

- Differential output

- AEC Q100 certification

- Robust performance in a high shock and vibration environment

- Wide temperature range

Our DSA series of MEMS oscillators makes an ideal automotive timing solution. They are small—down to 1.6 × 1.2 mm for CMOS and 2.5 × 2.0 mm for differential. They are rugged—able to withstand 50,000G shock and 70G vibration. They are stable—holding ±20 ppm frequency accuracy over a wide -55°C to 125°C temperature range. They are flexible—configurable to any frequency output, and multiple frequencies for multi-output parts. And you can get them fast, with samples available in as little as 48 hours.

To learn more about timing and ADAS, check out our video where we explore different timing solutions and components which make up ECUs in modern vehicles.

If you have an ADAS timing challenge, our field engineers and factory-based applications engineers would be happy to assist you in your design journey. We offer a broad selection of devices with exceptional reliability and stability over a significant range of temperatures. For more information, please visit our automotive timing web page.